| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TGMCO |

| Certification : | SGS |

| Price : | $40000-$50000/set |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 10 sets per month |

| Delivery Time : | 90 days after receipt of down payment |

Change Size Automatically Thickness 1-3mm CZ Roll Forming Machine With Hydraulic Punching

A. Summary

This machine use metal coil as material, through decoiler, leveling, punching, cut off, roll former. It is no need to remove any parts, through the PLC, automatic conversion to required size , that is, the different sizes is completed by adjusting the combined mould, and punching, fixed length and other processes are completed at one time, the production process is fast, stable and safe.

B. Machine Components

| Components | Qty |

| Decoiler | 1 set |

Roll former (include feeding, pinching and leveling structure, hydraulic punching, roll former, hydraulic cutting structure) | 1 set |

| Exit rack | 2 sets |

| Electrical control system | 1 set |

| Hydraulic control system | 1 set |

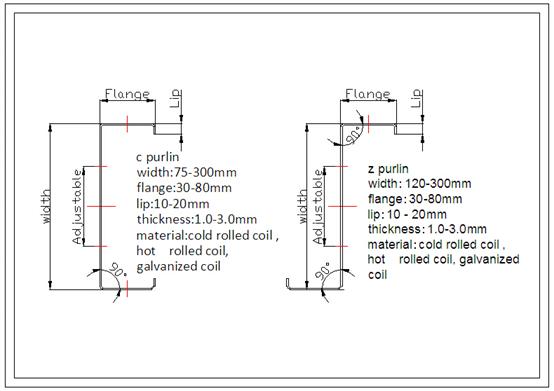

C. Drawings

D. Technical Flow

Manual decoiler → entry guide → pinching and leveling → hydraulic punching → roll former → hydraulic cut off → exit rack

E. Main Technical Parameters

1. Manual decoiler

1) Coil weight: max .5 tons

2) Decoiler: passive uncoiling, manual expansion

3) Decoiler range:Φ480-520mm

4) Coil OD: max,1550mm

2. Feeding & leveling

1) Stand: qualified welded profile steel

2) Guide feeding stand: side hand wheel type

3) Leveling type: 2 rolls pinching and 7 rolls leveling(3 top and 4 down )

4) Feeding and leveling motor power: 4kw

5) Leveling Shaft diameter: Φ90mm

6) Leveling Shaft material; 40Cr

7) Leveling shaft heat treatment: surface high frequency quenching

8) Leveling mechanism reducer: cycloid

3. Hydraulic Punching

1) Punching: hydraulic punching (4 positions, no need to change the mould when punching different hole types)

2) Material of up and down moulds: Cr12MOV

3) Up and down moulds heat treatment: Quench HRC58-60

4. Roll former

1) Roll former type: stand type and chain drive, steel plate welding (thickening type) stand

2) Shaft material: 40Cr hardening and tempering(HB220-260)

3) Bearing diameter: Φ80mm(HRB)

4) Forming motor power: 18.5kw

5) Transverse motor total power 3KW (0.75kw x2,1.5kw x1)

6) Roll former speed: 10-20m/min (exclude punch and cut time)

7) Forming station: 16 stations

8) Coil thickness: 1.0-3 mm

9) Spread width of rolling material: based on the actual width of the test plate

10),Tolerance:

Length tolerance ≤±1.0mm

Width tolerance ≤±0.5mm

Height tolerance ≤±0.5mm

11) Roll former mould: 1set (Automatic transverse movement of frame with different specifications)

12) Roller material: Gcr15 quenching treatment(HRC58-62)

13) Roller hard chrome coated layer≥ 0.05mm

14),C Z profile changed by manual 180 degree flip.

5. Hydraulic cut off

1) Cutting type: hydraulic cut off (Poleless structure with waste)

2) Blade material: Cr12mov

3) Blade heat treatment: quenching(HRC58-62)

6. Hydraulic station

1) Hydraulic system power: 11KW

2) Work pressure: 20Mpa

3) Solenoid Valve of Hydraulic System: Beijing Huade (24V Safety Voltage)

4) Hydraulic system oil pump: plunger pump

5) Cooling mod: air cooling

8. Electronic Control System

1) Inverter:Yaskawa

2) PLC:Panasonic

3) Touch screen:MCGS

4) Encoder: Omron

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust

you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS

assessment (Audit report can be provided). We have cooperated with

many customers all over the world with high market reputation, no

worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

- The pipe material

- Round pipe range

- Square pipe range

- Rectangle pipe range

- Wall thickness range

- The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil weight

- Cutting type

- Profiles drawings

- Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil width

- Coil weight

- Finished sizes

- Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

- Technical Support: TGMCO will provide detailed technical

information such as technical & commercial offer, machine

photos, running video, layout, operation manual, and show you

working machines in our factory.

- Apply Visa: TGMCO will provide officially invitation letter to

apply Visa in china embassy as authority procedures and

requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to

meet our customer need.

- Drawings: Provide the foundation drawing, electric scheme and

wiring diagram, hydraulic drawing, pneumatic & electric

pipeline drawing and other drawings requested by customer.

- Installation and commissioning: TGMCO will send our technicians to

customer's workshop for supervision of installation and commission

Training of Customers' technician/workers during commission

- Breakdown Support: We offer 1 year warranty service for main

crucial components except consumables

Inform immediate technical assistance and advice to customer by

phone or e-mail.

Skilled and experienced engineers are capable of dealing with any

type of breakdowns.

Technical service work performed in Customer's site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable

requirements

Packing & Delivery

|