| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TGMCO |

| Certification : | SGS |

| Price : | $70000-$10000/set |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 5 sets per month |

| Delivery Time : | 90 days after receipt of down payment |

Automatic Solar Frame Photovoltaic Support Stand Roll Forming Machine

A. Summary

This machine use metal coil as material, through decoiler, roll former, automatic length sizing, cutting off to form special size profile. The whole line use PLC control, AC frequency control to realize continuous automatic production.

B. Machine Components

| Components | Qty |

| Hydraulic decoiler | 1 set |

| Feeding Guide & Leveling Device | 1 set |

| Servo puncher | 1 set |

| Roll former | 1 set |

| Tracking cutting off structure | 1 set |

| Exit rack | 2 sets |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

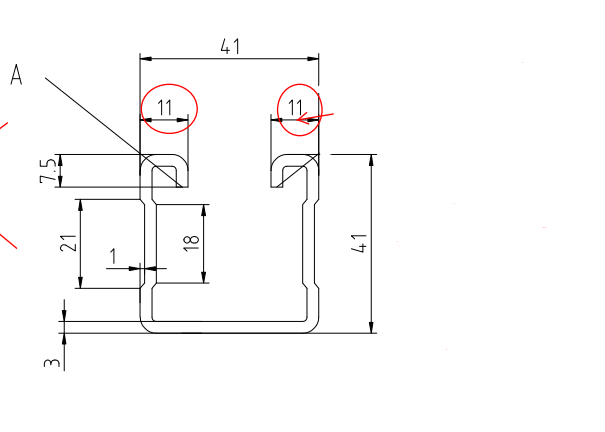

C. Drawing

D. Technical Flow

Hydraulic decoiler → Entry guide → Pinching and leveling → Hydraulic punching(80 tons puncher) → Roll former → Length sizing cutting → Exit rack

E. Main Technical Parameters

1. 5ton Hydraulic Decoiler

1) Decoiler: Structure of pedestal, braking, mandrel holder, slider narrow and expanding

2) Coil weight: max 4 tons

3) Coil ID: Φ508 mm

4) Coil OD: Φ1500 mm

5) Decoiler range:Φ450-540mm

6) Motor power: 4kw

7) Hydraulic power: 3kw

7) Hydraulic system oil pump: gear pump or vane pump

8) Solenoid Valve: Beijing Huade

9) Inverter: Yaskawa (Japan)

2. Feeding Guid & Leveling Device

1) Leveling width: ≤400mm

2) Leveling type: 2 rolls pinching and 5 rolls leveling (2 up and 3 down )

3) Feeding andLeveling motor power: 3kw

4) Leveling Shaft diameter: about Φ90mm

5) Leveling Shaft material: qualified 40Cr

6) Leveling shaft heat treatment: surface high frequency quenching

7) Reducer: Worm wheel and worm

3. Servo punching device

1) Servo feeding motor power: 2kw

2) Servo motor brand: Yaskawa

3) Puncher: JH21/80T

4. Main Roll Former

1) Guide feeding stand: side wheel type

2) Roll former type: cast iron stand type and gear box drive

3) Shaft material: 40Cr hardening and tempering(HB220-260)

4) Bearing diameter: Φ70mm(HRB)

5) Forming motor power: 22kw x 2

6) Roll forming speed: 10-20m/min (not include punching & cutting time)

7) Forming station: about 28 stations and a series of auxiliary rolls ( include roller teeth) roller teeth picture:

8) Adjust size: change spacer. Spacer is buckled type, loosen the locking round nut of the main shaft section, remove a spacer, install in the designated position, lock the round nut, and adjust the feed width, change the cutting mould can be produced.

9) Spread width of rolling material: based on the actual width of the test plate

10) Length tolerance ≤±1.5mm

11) Roller material: Cr12MOV quenching treatment (HRC58-62)

12) Hard Chromium Coating on Rollers: ≥ 0.05mm

13) Cutting mode: sawing (disc saw)

14) Saw blade material: high speed steel

15) Disc saw motor power: 3KW

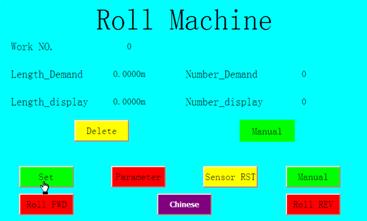

5. Electrical control system

The whole line controlled by PLC control and Frequency Speed Control to achieve automatic. The friendly interface can set the batch, product length and quantity.

PLC: Siemens/Panasonic

Encoder: Koyo/Omron

Buttons and contactors: Chint or Schneider

Operate panel: Touch screen

|