| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TGMCO |

| Model Number : | TG60 |

| Certification : | SGS |

| Price : | $200000-$250000/set |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 20 sets per month |

| Delivery Time : | 100 days after receipt of down payment |

Carbon Steel Φ25~Φ76mm TG60 Tube mill Line

Summary

This high-frequency welded tube mill is specialized equipment to produce high frequency longitudinal seam welded pipes for structural and industrial pipe with Φ25~Φ76mm and wall thickness of 1.0~3.0mm. Through optimized design, best materials choice, and accurately fabrication and rolls, the whole line can be reached high precision and high speed. within suitable range of pipe diameter and wall thickness, pipe production speed can be adjusted.

General technical specifications

1. Raw material requirements

Material: slited hot rolled or cold rolled steel coil

Tensile strength: σb≤600Mpa

Yield strength: σs≤315Mpa

Coil width: 80~240mm

Coil outer diameter: Max Φ1600mm

Coil inner diameter: Φ508mm

Coil weight: Max 3.5 tons

Coil thickness: 1.0~3.0mm

2. Output product scope

Pipe type: longitudinal seam high frequency welded pipes

Pipe purpose: Electric heating tube, fridge pipe, Auto car pipe, sporting facility tube, furniture pipe, cooler pipe, pressure feeding pipe, construction pipe, configuration pipe.

Round pipe size: Φ25~Φ76mm * 1.0~3.0mm

Square pipe size: 20×20~60×60mm *1.0~2.5mm

Rectangle pipe size: 15×25~80×40mm * 1.0~2.5mm

Production length: 4~8m (customized)

3. Line capability

Line direction: as per customer

Production speed: 30~80m/min

4. Scope of supply

4.1. Technology process:

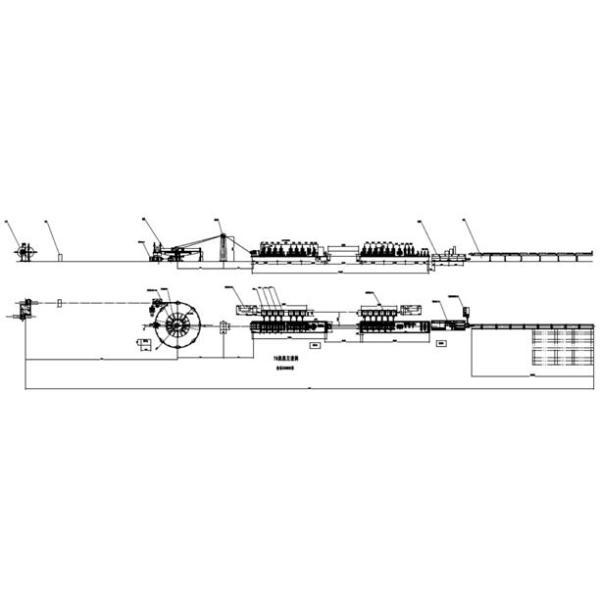

Uncoiler→ Shear & butt welder→ Horizontal accumulator→ Leveling→ Forming→ HF welding→ Deburring (outer) → Cooling→ Sizing→ Straightening→ Cold flying saw cut off→ Run out table

4.2. Parts of Line

Double heads uncoiler--------------------------------1 set

Shear & butt welder------------------------------------1 set

Horizontal accumulator------------------------------- 1 set

Forming & Sizing unit----------------------------------1 set

Cold flying saw cut off---------------------------------1 set

Run out table-------------------------------- ------------1 set

Electric control system---------------------------------1 set

Solid state high frequency welder-------------------1 set

Pneumatic system--------------------------------------Prepared by Buyer

Main structure

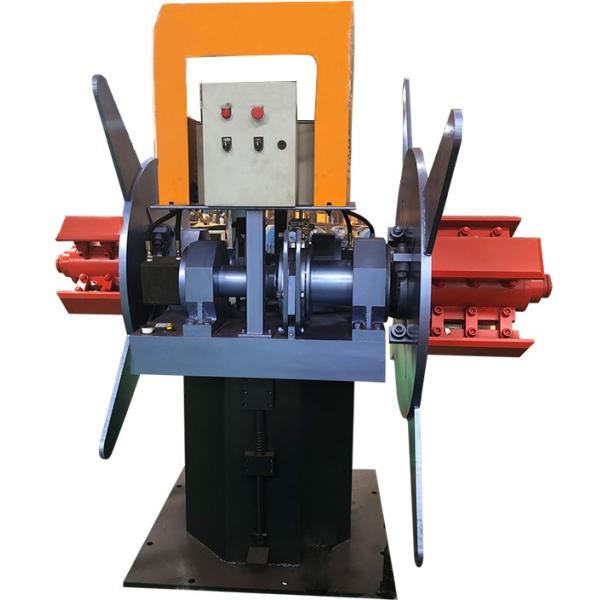

1. Double heads hydraulic uncoiler

Configuration: Two drums expansion by hydraulic

Coil ID: Φ508mm

Coil OD: ≤Φ1600mm

Coil width: 80~240mm

Coil weight: ≤3.5 tons

Brake type: pneumatic

Drums exchanging: 180° turning manually

2. TIG shear & butt welder

Shear the irregular part of 2 coils, then align and weld

| Structure type | Hydraulic shear, manual alignment, TIG automatic welding |

| Coil Width | 80 - 240mm |

| Coil Thickness | 1.0 – 3.0mm |

| Welding speed | 75 - 500mm/min |

3. Horizontal accumulator(outside feeding, center output)

Coil width: 80~240mm

Coil thickness: 1.0~3.0mm

Feeding speed: >=150m/min

Accumulator diameter: 4.5meters

Structure: consists of reversing stand, pinching unit (11kw AC speed adjusting motor), main body(15kw AC speed adjusting motor)

Control type: manual control feeding, share console with uncoiler, powerless output

4. Forming & Sizing unit

4.1. Forming & Sizing

4.1.1. Parts of Forming & Sizing:

Driving system-----------------------------------2 sets

Second grade transmission---------------------13 sets

Feeding & Leveling device----------------------1 set

Horizontal roll stand-----------------------------13 sets

Vertical roll stand--------------------------------17 sets

4.1.2. Driving system

Forming & Sizing driving system: 2 sets

Motor type: Z4 90kw/1500rpm

Reducer type: ZLY hard gear reducer

Motor driving system: Control by DC digital converter

4.1.3. Second grade transmission

Transmission type: Gear box and universal joint

Gearbox configuration: Spiral bevel gear & cylindrical helical gear

Lubricating: Gear oil soaking

Oil level display: Inspection glass on box

| Quantity | Spiral bevel gear | Gear box | |

| Forming unit | 7 | 20CrMnTi | HT200 |

| Sizing unit | 6 | 20CrMnTi | HT200 |

4.1.4. Horizontal roll stand & Vertical roll stand

Forming height: Φ150mm

Adjusting of Horizontal roller: Manual

Adjusting of Vertical roller: Manual sync screw adjusting

| Name | Section | Quantity | Shaft dia. | Material | Treatment |

| Horizontal roll stand | Forming unit | 7 | Φ70mm | 42CrMo | HF quenching |

| Sizing unit | 6 | Φ70mm | 42CrMo | HF quenching |

| Name | Section | Quantity | Shaft dia. | Material | Treatment |

| Vertical roll stand | Forming unit | 7 | Φ45mm | 40Cr | HF quenching |

| Sizing unit | 6 | Φ45mm | 40Cr | HF quenching |

4.2. Welding section

4.2.1. Parts of Welding:

Seam guide-------------------------------------1 set

Welding stand----------------------------------1 set

HF welder---------------------------------------1 set

Deburring cutter (Pneumatic) -----------------1 set

4.2.2. Welding stand

Type: 3 rollers

Shaft diameter: Φ50mm

Material of shaft: 40Cr (HF quenching)

Adjusting: Manual screw adjusting

4.2.3. Deburring cutter

Type: Two cutters setting

Feed/retract: Pneumatic adjusting

Cutter adjustment: Manual screw adjusting

4.2.4. Solid state high frequency welder

Type: High frequency induction welding

Size: GGP-200-0.4-HC

Power: 200kw

4.3. Cooling tank

Cooling way: Spraying and soaking

Length of cooling: 3500mm

4.4. Speed-measuring device

Type: Up-down 2 rollers type with pneumatic clamping

Quantity: 1 set

Outer dia. of roller: Φ111.4mm

Material of roller: Cr12

4.5. Turkey head straightening device

Type: single side and with 4 rollers

Configuration: Turning adjustment of top/bottom, left/right and rotation

Adjusting method: Manual screw adjustment

Shaft material: 40Cr (HF quenching)

Quantity: 2 sets

5. Cold Flying saw cut off system

Pipe end is smooth, clean and non-distortion end for square/rectangular pipe cutting, Leave out the process of chamfering, little noise with high cutting precision

Cutting type: AC servo motor conduct single saw cutting through ball screw, blade rotating is driven by AC motor through reducing box

Machine function: with function of manual, automatic, simulation and short size

Control system: 3 shaft digital control system (tracking & cutting & rotating shaft)

Mechanical parts: bed, saw cart, speed measuring device, tube input, output guiding device

Electronic parts: operation panel, control cabinet, motion controller, encoder, travel switch

Main parameters:

Pipe size: Φ25~Φ76mm, thickness: 1.0~3.0mm

Cutting length: 4 -8 meters

Cutting precision: ±2 mm

Saw blade: HSS 450mm

Max speed: ≤80m/min

Driving motor: 15kw Yaskawa AC servo motor

Cutting motor: 15kw AC motor

Feeding motor: 4.4kw Yaskawa AC servo motor

Clamping: pneumatic

6. Run out table

Configuration: welded profile steel and pipe frame type

Length: 11.5m

Discharging speed: 130m/min

Driving motor: AC 3kw

7. Roller/Tool (quote separately)

7.1. Forming and Sizing rollers

Material: Cr12(JIS-SKD1, ASTM-D3)

Hardness: Surface quenching HRC 60 ± 2; critically grinding

7.2. Welding roller

Material: H13 (JIS-SKD61, ASTM-H13)

Hardness: Surface quenching HRC 50 ± 3; critically grinding

8. Brands of main parts

| NO | Parts name | Brand | Remarks |

| 1 | Main motor | Xi’an SIMO | Top brand in China |

| 2 | Motor driver (DC digital converter) | PARKER | |

| 3 | Bearing | HRB, LYC, ZWZ | Top brand in China |

| 4 | Pneumatic element | AIRTAC | Top brand in China |

Scope of supply of buyer

Site area of machine (length X Width): 58m × 7m

Site area of cabinets (length X Width): 6m × 3m

Machine foundation base: See foundation drawing CAD

Overhead crane: 2 sets of ≥5 Tons overhead crane

Ferrite rod: prepared by Buyer

Saw blade: Prepared by Buyer

Lubricating oil grease, cooling emulsion and etc will be prepared by Buyer

One set of Emulsion water cooling pool(Volume≥30 m3 pool)for pipe mill and plate exchanger of HF-welder, with two sets of pumps(AC4kw, lift≥30m & flux 30m3/hour),water pressure meter,valves,and water pipes will be prepared by Buyer. Or use one set of glass steel cooling tower for Emulsion water cooling pool and plate exchanger of HF-welder.

Adopting ground or attic frame and room of high-frequency welder for machine unit, stack basket for welded pipe, made by buyer.

The cables which from power station to tube mill line, and cables & wires between machines and cabinets, all of them will be prepared by Buyer.

One set of ≥1m3 /min air compressor, 0.7~1.0Mpa output, and one set ≥0.5m3 air tank, Entire pneumatic supply system will be prepared by Buyer.

Lifts, tools, anchor bolts, expand bolts, embedded and fixing materials for installing machine will be prepared by Buyer.

Power supply:

High frequency welder power: GP-200kw

Power of supply: 3P/4W/380V/50Hz

Total power of Line: 450Kw

|