| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TGMCO |

| Certification : | SGS |

| Price : | $15000-$25000/set |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 5 sets per month |

Round and Square Gutter Roll Forming Making Machine

Product description

We have marked a distinct and dynamic position in the market by

providing a high-quality array of Downspout Roll Forming Machine

that is fabricated under the guidance of our skilled professionals

using the latest technology in compliance with international

quality standards. This Downspout Roll Forming Machine is widely

used in the production industry for making downpipe. Our offered

Downspout Roll Forming Machine is praised among our clients for its

attributes like high performance, excellent functionality, sturdy

construction, low maintenance, and reliability.

Machine components

| No. | Name | Qty |

| 1 | 3T Manual Decoiler | 1 set |

| 2 | Feeding Device | 1 set |

| 3 | Roll Former | 1 set |

| 4 | Cutting Device | 1 set |

| 5 | PLC Control System | 1 set |

| 6 | Hydraulic Station | 1 set |

| 7 | Output Table | 2 sets |

Main Technicial Parameter of Downpipe roll forming machine

No. | Main parameter of gutter roll forming machine |

1 | Suitable to process Color steel plate |

2 | Width of the plate 200-600mm |

3 | Rollers 24rows |

4 | Dimensions 8.6*0.8*1.2m |

5 | Power 4+3kw |

6 | Thickness of the plate 0.3-0.8mm |

7 | Productivity 8-12m/min |

8 | Diameter of the roller 5tons |

9 | Weight About 5 T |

10 | Voltage 380V 50Hz 3phases |

11 | Rolling material Carbon Steel 45# |

12 | Material of the cutting plate Cr12 |

13 | Processing precision Within 1.00mm |

14 | Control system PLC control |

15 | Side panel of machine 14mm |

16 | Main structure of the machine 300 H steel |

17 | Weight About 4.5 T |

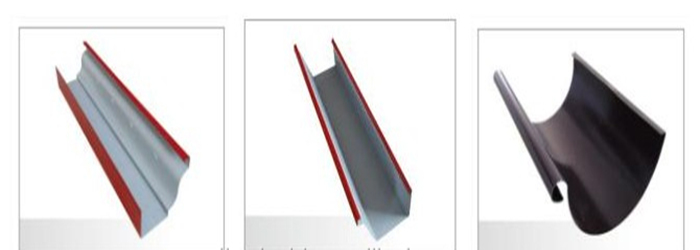

Profile Drawing

Working flow

Decoiler—Feeding—Main Roll forming—Hydraulic Cutting—Output table

Machine Components

1. Manual decoiler

1). Coil weight: max .3 tons

2). Decoiler: passive uncoiling, manual expansion

3). Expansion range:Φ480-520mm

4). Coil OD: max,1500mm

2. Feeding guide

1). Stand: qualified welded profile steel

2). Guide feeding stand: side hand wheel type

3. Maim Roll former

1). Roll former type: wallboard type and chain drive

2). Forming station: about 18 stations(depend on the actual drawing)

3). roller material: 45# steel chrome coated polishing treatment

4). Roller shaft material 45#steel, shaft diameter: Φ75mm

5). Manual screw adjusts the gap between up and down rollers to suit plate with different thickness

6). Spread width of rolling material: based on the actual width of the test plate

7). Roll former mould: 1set

8). Length tolerance ≤±1.5mm

4. Hydraulic cut off

1). Cutting type: hydraulic cut off

2). Blade material: Cr12mov quenching treatment

3). Cut-off power provided by hydraulic station

6,Necking device

1). The device can reduce the downspout port and facilitate lapping.

2). Necking mould material: Cr12 quenching treatment

3). Power provided by hydraulic station

7. Exit rack: 2 sets

7. Hydraulic station

1). Hydraulic system power: 11KW

2) . Solenoid Valve of Hydraulic System: Beijing Huade (24V Safety Voltage)

3) . Hydraulic system oil pump: plunger pump

4) . Cooling mod: air cooling

8. Electric control system

1). Inverter:Yaskawa

2). PLC:Panasonic

3). Touch screen:MCGS

4). Encoder: Omron

Picture for reference

Packing & Delivery

|