| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | TGMCO |

| Certification : | SGS |

| Price : | $20000-$45000/set |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 5 sets per month |

Pallet Rack Step Beam Roll Forming Machine

Roll forming machine can replace the ball mill pre grinding system with high energy consumption and low efficiency, and reduce the steel consumption and noise. It is suitable for the construction of new plants, and can also be used for the technical transformation of old plants. The output of the ball mill system is increased by 30-50%. In the extruded material cake, 0.08mm fine material accounts for 20-35%, less than 2mm for 65-85%. The internal structure of small particles is full of many micro cracks due to extrusion The grindability is greatly improved. The roller surface adopts hot surfacing, so the maintenance of wear-resistant layer is more convenient.

The common roller press is composed of roller, frame, roll distance

adjusting device, transmission device, lubrication system,

control system and roll dismantling device. In addition to the main

parts and devices of ordinary calender, the precision roller press

has added devices to ensure calendering accuracy, such as pressure

maintaining system, bearing clearance adjusting system,

etc.

Machine components

| No. | Name | Qty |

| 1 | 5 Tons Manual Decoiler | 1 |

| 2 | Feeding & Leveling Device | 1 |

| 3 | Main Roll Forming Machine | 1 |

| 4 | Hydraulic Cutting Device | 1 |

| 5 | PLC Control | 1 |

| 6 | Hydraulic Station | 1 |

| 7 | Output Table | 2 |

Technical parameters

| Items | Items | Specifications |

| Material of coil | Material Width | 100-800mm |

| Material Thickness | 1.5-3.0mm | |

| Decoiler | 5 tons | |

| Feeding&Leveling | 5 Rollers Leveling | 2rollers up, 3rollers down |

| Forming system | Forming Speed | 5-15m/min |

| Forming Stations | about 14-18 stations | |

| Roller Material | Gcr15, Quench Hrc58-62, Plated Chrome | |

| Shaft diameter | 60-90mm | |

| Shaft Material | High Grade 45# steel | |

| Main Motor Power | 15-35kw | |

| Machine structure | Archway or wall panel | |

| Transmission | Gear box or chain | |

| Cutting system | Hydraulic Power | 5.5-7.5kw |

| Cutting blade | Cr12Mov,quenching HRC 58-62 | |

| Tolerance | +-1.5mm | |

| Electrical control system | Electric Source | 380V, 50HZ,3 phase |

| PLC Control System | Siemens/Panasonic |

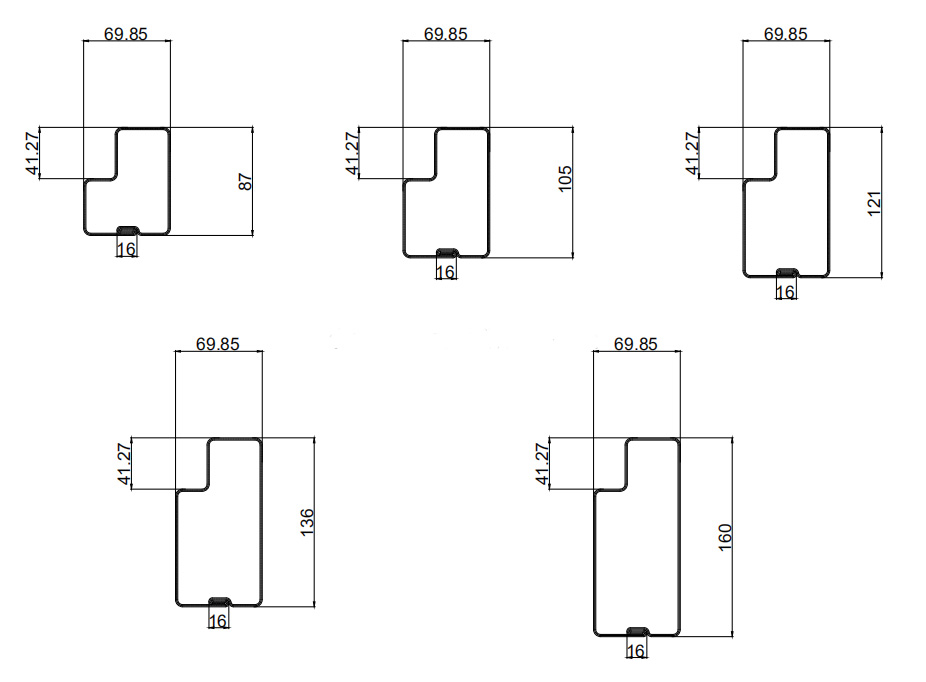

Profile drawing

Working flow

Decoiler—Feeding&Leveling—Main Roll forming—Cutting—Output table

Picture for reference

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust

you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS

assessment (Audit report can be provided). We have cooperated with

many customers all over the world with high market reputation, no

worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

- The pipe material

- Round pipe range

- Square pipe range

- Rectangle pipe range

- Wall thickness range

- The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil weight

- Cutting type

- Profiles drawings

- Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil width

- Coil weight

- Finished sizes

- Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

- Technical Support: TGMCO will provide detailed technical

information such as technical & commercial offer, machine

photos, running video, layout, operation manual, and show you

working machines in our factory.

- Apply Visa: TGMCO will provide officially invitation letter to

apply Visa in china embassy as authority procedures and

requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to

meet our customer need.

- Drawings: Provide the foundation drawing, electric scheme and

wiring diagram, hydraulic drawing, pneumatic & electric

pipeline drawing and other drawings requested by customer.

- Installation and commissioning: TGMCO will send our technicians to

customer's workshop for supervision of installation and commission

Training of Customers' technician/workers during commission

- Breakdown Support: We offer 1 year warranty service for main

crucial components except consumables

Inform immediate technical assistance and advice to customer by

phone or e-mail.

Skilled and experienced engineers are capable of dealing with any

type of breakdowns.

Technical service work performed in Customer's site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable

requirements

Packing & Delivery

|